bending machine problems|cnc press brake not bending : sourcing By understanding these common problems and their solutions, operators can effectively diagnose and address issues with their sheet bending machines. Regular maintenance and proper operating techniques can help prevent these problems from occurring in the first place, ensuring efficient and high-quality sheet bending operations.

WEB23 de jan. de 2024 · Uma dessas maneiras é apostar nas partidas de StarCraft 2. Este guia oferece uma visão geral abrangente de como fazer apostas no SC2, .

{plog:ftitle_list}

WEBInternationalCupid is a dating site that connects singles from different countries and cultures. Find your perfect match, read success stories, and join for free today.

Pipe, tube and profile bending machine Congratulations on your purchase of an Ercolina® bending machine from CML USA, Inc. Ercolina® machines are designed and manufactured to deliver years of trouble-free bending performance. Please take a moment to complete and mail the warranty registration card. Doing so validates machine warranty period 1. Machine not bending accurately: – Check the alignment of the bending dies. – Inspect the material for any defects or irregularities. – Calibrate the machine according to the manufacturer’s instructions. 2. Metal cracking or tearing during bending: – Use a sharp bending die that matches the thickness of the material.Definition of Bending Machine? Bending Machine: Definition, Types, Parts, Working, Application & Advantages :-A bending machine is referred to as a primarily used machine which is mainly used to form a bend on any required . Bending pipe and tube often is described as a black art, which characterizes the precarious nature of quality and repeatability. The myriad factors that can affect bending do so by impeding efficient production, compromising setups, shortening the time required between machine adjustments, or compromising the aesthetic appearance or strength of the finished .

Troubleshooting this type of problem requires an understanding of how each axis on the machine is homed. Homing and the Control System For safe operation of a CNC tube bender, the control system must know the position of anything that moves on the machine—clamp die, pressure die, bend arm, carriage, collet. By understanding these common problems and their solutions, operators can effectively diagnose and address issues with their sheet bending machines. Regular maintenance and proper operating techniques can help prevent these problems from occurring in the first place, ensuring efficient and high-quality sheet bending operations.

This is particularly true with CNC bending machines with modern software and equipment. Reduced Post-Processing – Other fabrication processes require post processing before a part is complete. Heat used in welding, for example, can cause dimensional distortion in a sheet metal part. Straightening may be required to correct this.a rotary-draw tube-bending machine. We describe four simple steps for setting up a complete set of tools on a machine, which if executed . a forward mandrel position with lower machine pressures solves these problems. For further assistance, phone us toll-free 800-284-8823 or visit our website, www.bendtooling.com . This article presents various ways to solve the accuracy of press brake bending problems for press brake manufacturers in the metal forming and fabricating industry. These methods include the selection of bending method, the leveling and compensation mechanism of the machine, the choice of bending materials, and the precision bending parameters.

Founded in 1992 by Constantine Grapsas, AIM Inc. has grown to become the premier CNC bending machine supplier serving customers worldwide. AIM Inc. has been solving customer application problems from Day 1. The first AIM Inc. machine produced repeatable and highly accurate parts fast and efficiently. We've assembled a list of some of the most common sewing machine problems, and their solutions, to help you troubleshoot even while mid-project! 1. Thread bunching up under your fabric when sewing . but you continue to have issues with breaking or bending, you may have underlying mechanical issues with the timing mechanism, which will require .

Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the . Knowing how to reset a vending machine provides a quick, though not foolproof, way of fixing vending machine problems. Since vending machines rely on sensors and mechanisms to function, turning them off and back on sometimes solves errors with no root cause. If resetting the vending machine solves the problem, you should still complete . If there is a problem when using the pipe bending machine, it should be dealt with in time to avoid unnecessary losses. Wonsten® Group Wonsten® Group 531 followers .

Troubleshooting sheet bending machine issues requires a systematic approach, addressing potential problems in different aspects of the machine. By following these tips and consulting the manufacturer’s guidelines, operators can effectively identify and resolve issues, minimizing downtime and ensuring optimal machine performance. . A plate rolling machine, also known as a plate roller or sheet metal roller, is a specialized machine tool designed for continuously bending metal sheets into cylindrical, conical, or arc-shaped workpieces.This versatile equipment utilizes the principles of plastic . Using the information contained in the template, VGP3D knows the material behavior, even for a different part geometry.. The VGP3D template contains all the information about the machine, the tool-set and most .

The rust, dust, and filings from bar bending processes could cause respiratory problems over time. Additionally, one might develop eye complications due to prolonged exposure to flashing lights associated with cutting or heating steel bars. . Role of bending machines in construction projects. Like other equipment, bar bending machines play a .manual roller bending machine, the gear mechanism, power transmission, speed controller. In . 9 simple words, most specifications are linked with the theory of machines. Since the project's objective is to design a manual roller bending machine, the concepts of mechanisms must beBy identifying the root cause of the stitching problem, you can take the necessary steps to correct it. In addition to stitching problems, Juki sewing machines can also experience issues with the bobbin, needle, or feed dogs. Bobbin problems can include thread bunching or tangling, while needle problems can include breaking or bending. 1 likes, 0 comments - bendingwirerod on September 23, 2024: "If you want to know about wire bending machine, please contact us How does wire bending machine solve production problems How does wire bending machine save bending die How does wire bending machine save labor costs How does wire bending machine improve production .

Replace any damaged parts promptly to prevent further damage and ensure the machine’s efficiency. Troubleshooting common problems. Familiarize yourself with common issues that may arise during the operation of the rebar stirrup bending machine, such as irregular bending angles or excessive noise.

If your singer’s heavy-duty 4423 sewing machine doesn’t have a built-in needle threader, then you can go for a handheld needle threader. 8. Have a Cleaning & Maintenance Protocol. Most of the problems with Singer 4423 heavy-duty sewing machine occur because of poor maintenance or cleaning. 1. Uneven Bending. Problem: Inconsistent angles or curves in the bend. Solution: Check and adjust the tooling, ensure proper material alignment, and verify the machine’s alignment. 2. Springback. Problem: After bending, the material returns partially to its original form. Solution: Increase the bend angle slightly or use a smaller inside bend .

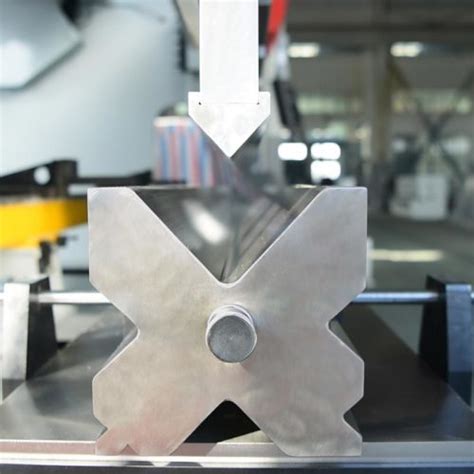

Press brake bending machines are essential tools in metalworking, but like any machinery, they can experience occasional problems. This article provides guidance on troubleshooting common issues that arise with press brake bending machines, enabling you to quickly resolve issues and maintain optimal performance. Material Quality and Preparation . We manufacture a Steel Bending Machine to bend sheet metal edges. Hydraulic Press Machines are used in metalworking industries. . Common Issues and Troubleshooting. Misalignment of the die and punch: Adjust the alignment to ensure precise bends. Inconsistent bending angles: Check for wear on the tools and replace if needed. . Press brake bending machines are essential equipment in the metalworking industry, used for bending sheet metal into a variety of shapes. However, like all machines, they can encounter problems that require repairs and troubleshooting. To ensure efficient and safe operation, it is crucial to understand the common issues and their solutions.

cnc press brake problems

used car compression test

used compression testing equipment

web7 de fev. de 2023 · XCIPTV PLAYER para PC Windows usando o NOX App Player. Primeiro de tudo, você deve baixar o player Nox App - https://www.bignox.com, clique no software para iniciar a instalação em seu computador / laptop. Após a instalação, abra o player NOX. Na caixa de ferramentas do canto direito, você encontrará uma opção de " Adicionar APK ".

bending machine problems|cnc press brake not bending